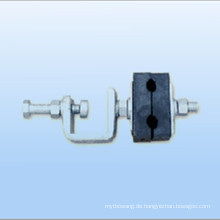

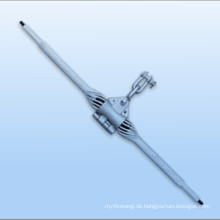

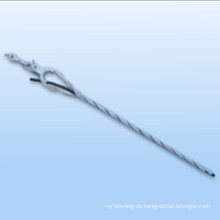

Harz-Sand-Guss-Teil für mechanische Teile

Harz-Sand-Guss-Teil für mechanische Teile

| Zahlungsart: | L/C, T/T, D/P, Western Union, Paypal |

|---|---|

| Minimum der Bestellmenge: | 50 |

| Lieferzeit: | 1 Tage |

| Produktivität: | 5000 Piece/Pieces Per Month |

|---|---|

| Ort Von Zukunft: | Hebei, China |

| Versorgungsmaterial-Fähigkeit: | 5000 Piece/Pieces Per Month |

| Zertifikate : | SGS, ISO 9001 |

Basisinformation

Modell: iron casting

Produktbeschreibung

Modell Nr .: Eisenguss Gussteilverfahren: Richtungskristallisation Anwendung: Maschinenteile Material: Eisen Oberfläche Rauheit: Ra0.8 Größe: Entsprechend Ihren Zeichnungen Warenzeichen: Mingda Spezifikation: SGS Typ: Clay Trockener Sand Sand Kernart: Harz Sand Core Bearbeitung: CNC-Bearbeitung Oberflächenbehandlung: Sand Blast Zertifizierung: SGS, ISO 9001: 2008 Prozess: Shell Casting, Sand Gießen Transport Paket: Standard Export Paket Herkunft: Hebei, China

Harz-Sand-Guss-Teil für mechanische Teile

Harz Sand Eisen Gussteil Teil für mechanische Teile, duktiles Eisen, grau Eisen grün Sand Casting Teil für

Engineering, Gusseisen, Sphäroguss, Grauguss-Guss industrielle Lieferanten, Gussteile, Gießen, Sand

Gießen, Aluminiumguss, Maschinenteile, Bearbeitungsteile, Metallteile, Präzisionsguss, Maschine

Ersatzteile, Stahlguss, Gusseisen-Gussteile, Gusseisen-Gussteile, Aluminiumguss

Teile und CNC-Bearbeitung, Um Ihnen zu entsprechen, können wir auch Montage der Produktion und Zeitraum;

Vorteile:

Über 10 Jahre Erfahrung

Qualitätskontrolle, konkurrenzfähiger Preis, Anlieferung auf Zeit u. Zeitraum;

Kleine Menge akzeptabel

Beispiel vorhanden

OEM bearbeitbar

One-Stop-Service

ich

SO9001: 2008

FAQ

Harz-Sand-Guss-Teil für mechanische Teile

Harz Sand Eisen Gussteil Teil für mechanische Teile, duktiles Eisen, grau Eisen grün Sand Casting Teil für

Engineering, Gusseisen, Sphäroguss, Grauguss-Guss industrielle Lieferanten, Gussteile, Gießen, Sand

Gießen, Aluminiumguss, Maschinenteile, Bearbeitungsteile, Metallteile, Präzisionsguss, Maschine

Ersatzteile, Stahlguss, Gusseisen-Gussteile, Gusseisen-Gussteile, Aluminiumguss

Teile und CNC-Bearbeitung, Um Ihnen zu entsprechen, können wir auch Montage der Produktion und Zeitraum;

|

Material range: |

stainless steel, cast iron, pig iron, carbon steel, alloy steel, non-ferrous, grey iron, ductile cast iron,etc |

|

Process Type: |

lost wax casting, soluble glass casting, ductile iron casting, sand casting, die-casting,cnc machining ,ect |

|

Surface: |

polishing, machining, plating, Heat Treatment, painting,ect. |

|

Finish: |

Zinc plated, Chromated plated, Electrophoresis, Powder coating, Anti-corrosionetc |

|

Standard: |

OEM manufacturing as per customers requirements or drawings. |

|

Application: |

Industrial parts, Machinery parts, construction parts, valve parts, train, craft, door handle, hinge, hydraulic pressure, construction, agricultural machinery, auto parts,ect. |

Vorteile:

Über 10 Jahre Erfahrung

Qualitätskontrolle, konkurrenzfähiger Preis, Anlieferung auf Zeit u. Zeitraum;

Kleine Menge akzeptabel

Beispiel vorhanden

OEM bearbeitbar

One-Stop-Service

ich

SO9001: 2008

FAQ

|

1:Are you a factory or trading company? Hebei Mingda is a direct factory that specializes metal castings and machining ,which is located in in the international sea port city of Ningbo ,east of china . Sanheng has 100 employee , among of them ,senior engineer and technician total of 5 people. 2:Do you have quality control system? |

|

Yes,we has certificated with ISO9001:2008 , All products will be passed full inspection before delivery. 3: What's your material scope? Mingda uses the material carbon steel, steel alloy, stainless steel, gray iron, ductile iron,cast iron, brass, bronze, aluminum alloy etc. 4.How much accuracy you can reach? Mingda's machining accuracy can be up to +/-0.005mm. 5. Where are rough casting from? Mingda has many excellent partners of casting and forging field. We can filter the most suitable one according to the casting complexity and your requirements. 6. Can you provide surface treatment ? Yes, we will provide you surface treatment, such as shot blasting, electroplating, hot-dip galvanizing , powder coating, chrome coating, phosphate coating, polishing etc. it depends on your requirement. 7. I just have a sample, Could you help to produce the products for me ? Yes, we can copy the product for you even better ,We can make the drawings for free of charge for you from your sample. Total step as the following. step 1, send us the sample. step 2, we will analyze the meterial composition after receiving samples, meanwihle we make the drawings for both casting and machining, then send you for confirmation. step 3, Mould making . Step 4, Sample making according to the final drawings Step 5. samples delivery for your confirming. Step 5, Mass production after your permission. Step 6, QA quality verify and controll the production risk. Step 7, Products delivery Step 8, Service after sales. 8. I'm not familiar with the shipping and transportion, can you give me some assistance for it ? Sure, we have professional logistic operater for international shipment. We can provide you the service Door to Door. |

Produktgruppe : Gusseisen und Grauguss > Eisenguss

Premium Related Products

andere Produkte

heiße Produkte

Kaltkammer ADC-12 Druckgussgehäuse für Solarstraßenlicht0001371006 LKW-StarterServo Motor Anwendung, Aluminiumguss ErsatzteileDruckgussgriffKommunikation Ausrüstung Druckguss Telekommunikation TeileStanzteile Möbel Hardware Funiture BracesStanzteile Stamping Outdoor Kamera SchildDruckguss-LED-Lampen-FrontabdeckungenCCTV-Überwachungskamera-Haube-Fall-TeileStanzen von BlechbearbeitungKundenspezifische Druckguss-AutoteileLow-Cost-Qualität Aluminium führte Kühlkörper Profil PreisProfessionelle Kundenspezifische Teile / CNC Präzisionsbearbeitung Teile2016 heiße Verkauf hohe Präzision Aluminium StanzteileAluminium-Druckguss-kundenspezifische MotorgehäuseteileBest Selling Produkte Aluminium Druckguss